Medical research is expanding to repair large bone defects resulting from trauma, tumour or infection. The most common method is bone autotransplantation using the patient's own bone tissue, but this has its own undesirable effects (pain, tingling, risk of infection, etc.). Osteoinductive medical devices currently under development will be evaluated in a preclinical model on long-bearing bone.

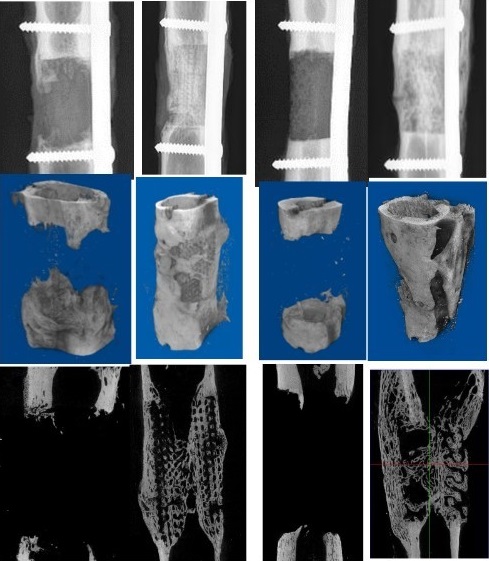

Researchers from the Biosanté/BRM team have collaborated with the [consortium] to develop an innovative medical device to repair a 25 mm-long defect in a sheep metatarsal, with no side effects. The new device consists of a porous structure in the form of a 3D-printed scaffold made of polylactic acid (PLA), a biocompatible, clinical-grade polymer. This structure is coated with a polyelectrolyte film delivering bone morphogenetic protein 2 (BMP-2), which generates bone tissue formation. The biocompatibility of the device materials was tested

in vitro and

in vivo. Different scaffold geometries were produced. The results of the

in vivo tests showed that the internal geometry of the scaffold, in particular the shape of the pores, had an influence on bone regeneration, which was homogeneous in the longitudinal direction. After 4 months of implantation, scaffolds with cubic pores of around 870 µm, and a low dose of BMP-2, of the order of 120 µg/cm3, induced the best bone regeneration without adverse effects, with clinical results close to those obtained with the reference method, which is autografting.

The study of this new strategy for reconstructing long bones opens up prospects for personalized bone regeneration. However, the materials and geometry of the device need to be optimized, and longer-term studies carried out, before clinical application can be envisaged.

Figure: X-ray images (top row) 3D scanner images (middle row) and 2D scanner images (bottom row) showing the reconstruction of a sheep metatarsal with two scaffolds of different geometries and coated (columns 2 and 4) or not coated (columns 1 and 3) with the osteoinductive molecule BMP-2.

© Garot et al. Adv Healthcare Materials 2023

Consortium

- BRM Biomimetics and Regenerative Medicine (UMR Biosanté CEA/CNRS/Inserm/Université Grenoble Alpes)

- B3OA Bone and Joint Biology, Bioengineering and Bioimaging (CNRS/Inserm/Université Paris Cité)

- ENVA École vétérinaire d’Alfort, IAB Institut pour l’Avancée des Biosciences (CNRS/Inserm/Université Grenoble Alpes)

- CIC-IT Centre d’investigation clinique - innovation technologique de Bordeaux (Inserm/CHU de Bordeaux/ Institut Bergonié/Université de Bordeaux)